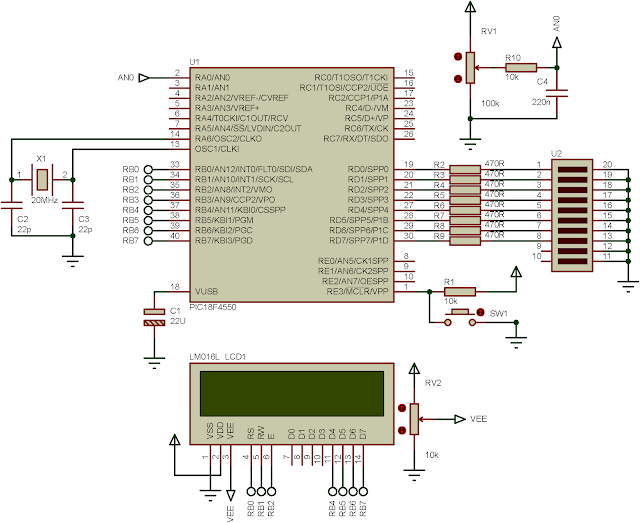

A character LCD traditional built with a controller inside especially the HD44780. It's easy to control with some basic LCD instruction. For more technical details and programming interface for this type of LCD controller click here to view. Character LCD are available from as single to multiple lines and multiple characters.

|

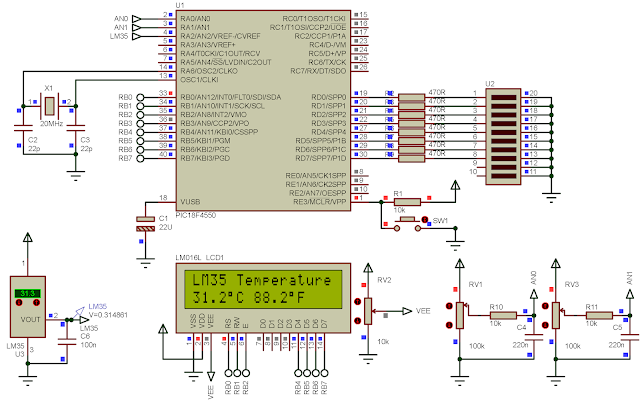

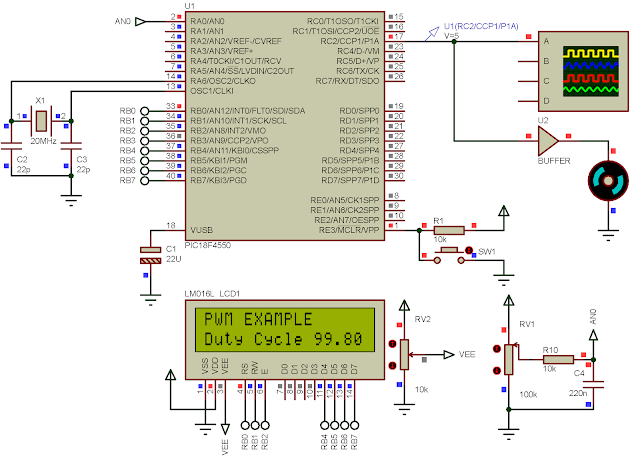

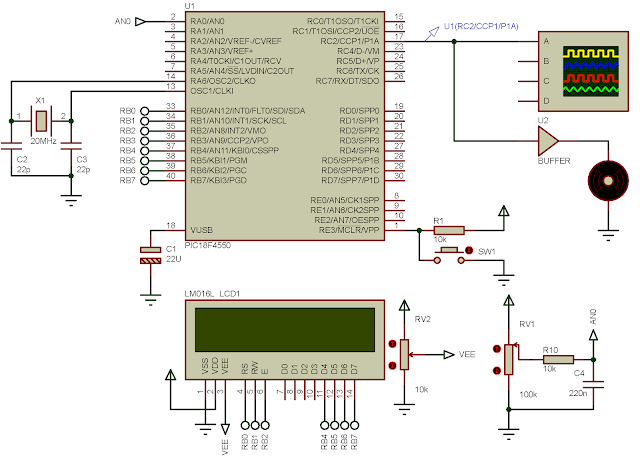

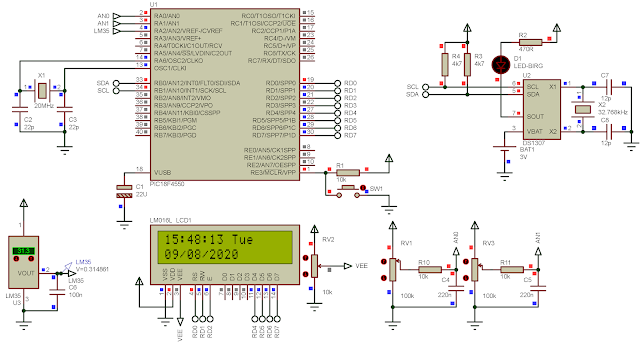

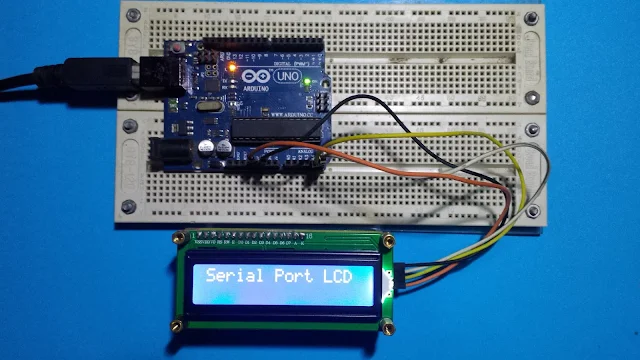

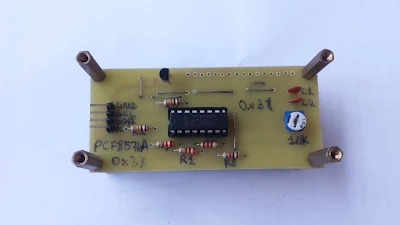

| A running Program |

In CCS PIC an LCD software driver is ready to use in side the compiler. The LCD.C driver could control a character LCD only for two line character LCD. Within this driver there are a lot of functions lists below.

- lcd_init() - must be called before calling other function

- lcd_putc() - send one character to LCD

- lcd_gotoxy(x,y) - set write position on LCD, start from 1,1

- lcd_getc(x,y) - return character at the position x,y on LCD

- lcd_cursor_on(int1 on) - turn on cursor

- lcd_set_cgram_char(w,*p) - write custom character to CGRAM

|

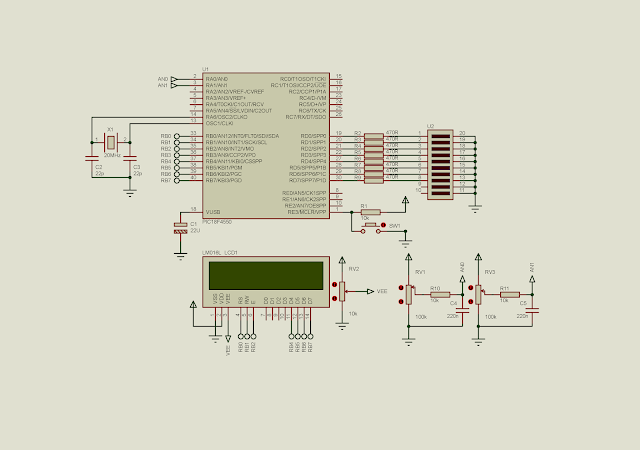

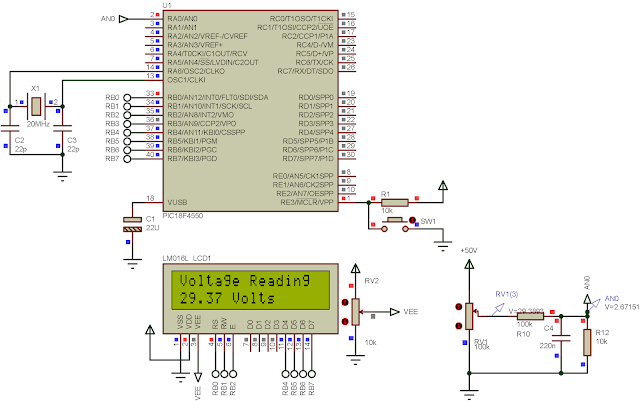

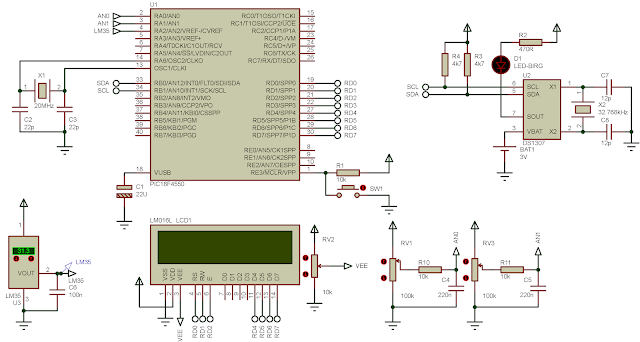

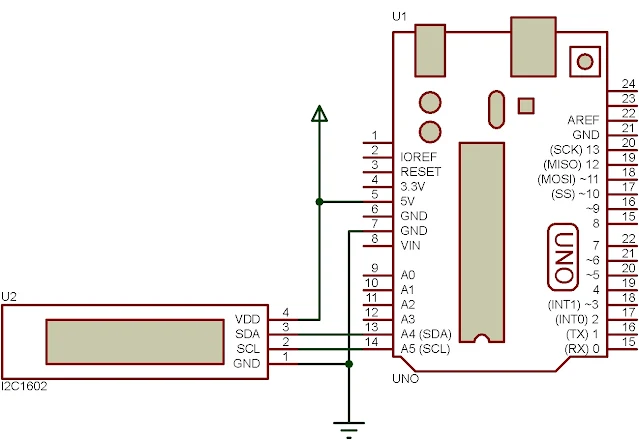

| Schematic Diagram |