|

| Bipolar stepper motor (Model 42BYGH34-0400A) with 1.8 degree step angle. |

It is made of two distinct coils, but each coil is separated a much as possible around the rotor, to make stepping angle much smaller.

|

| Diagram of common bipolar stepper motor. This motor come from the Chinese company as shown in the picture above. |

To make it step look at the time diagram below:

|

| Timing Diagram for stepping clock wise and counter clock wise |

Difference bipolar stepper motor has difference stepping angle. We can check its spec before use.

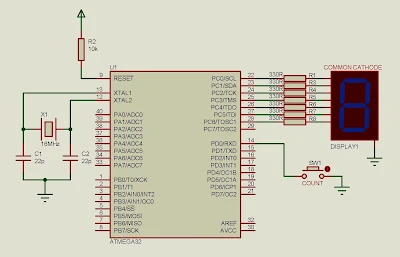

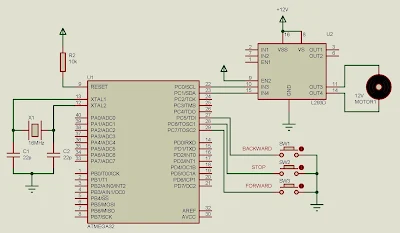

The example below just like the previous example. I use a switch connects to PD7 to control the stepping direction of the bipolar stepper motor.

|

| A bipolar stepper motor connects to PORTC. PD7 is used for controlling the direction. |

Source code:

#include <avr/io.h>

#define F_CPU 16000000UL

#include "util/delay.h"

#define stepTime 100

//clock wise stepping

void stepCW(){

PORTC=0b00001100;

_delay_ms(stepTime);

PORTC=0b00000110;

_delay_ms(stepTime);

PORTC=0b00000011;

_delay_ms(stepTime);

PORTC=0b00001001;

_delay_ms(stepTime);

}

//counter clock wise stepping

void stepCCW(){

PORTC=0b00001001;

_delay_ms(stepTime);

PORTC=0b00000011;

_delay_ms(stepTime);

PORTC=0b00000110;

_delay_ms(stepTime);

PORTC=0b00001100;

_delay_ms(stepTime);

}

int main(void)

{

DDRC=0xFF;

DDRD=0x7F;

PORTD=0x80;

while (1)

{

if((PIND&0xFE)==0) stepCW();

else stepCCW();

}

}