A servo is a kind of motor built in a module. The module contains a DC motor and a feed back control circuit. The feed back circuit regulates the motor rotating position to a specific angle receives from its master MCU, for example and Arduino.

|

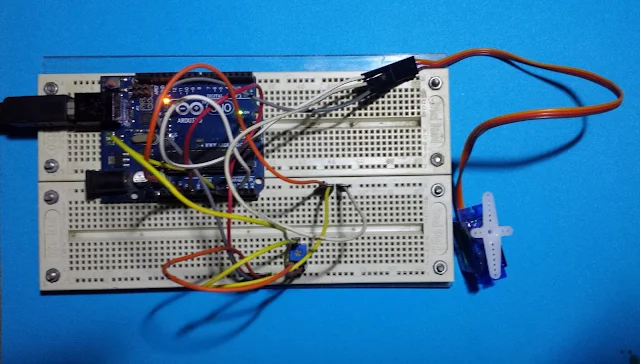

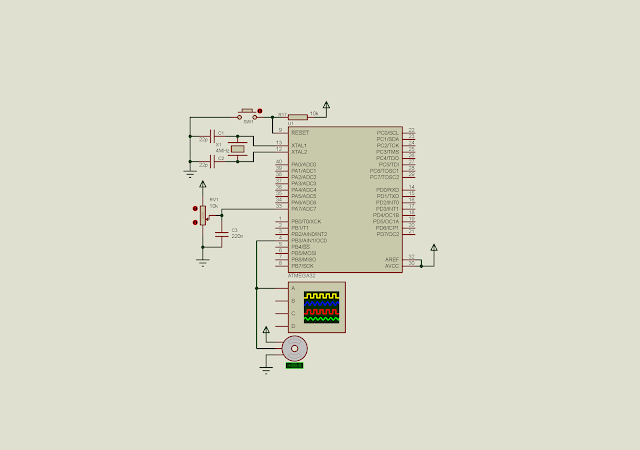

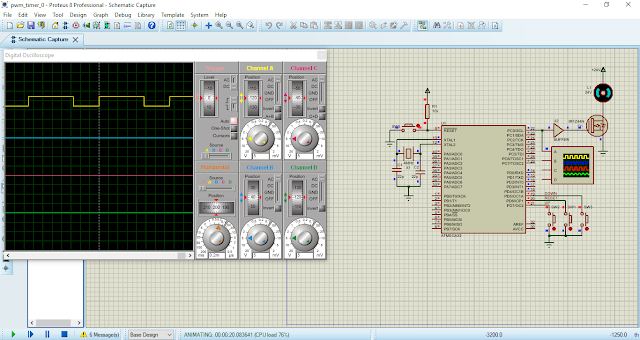

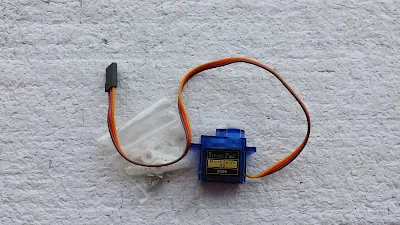

| Picture of this example |

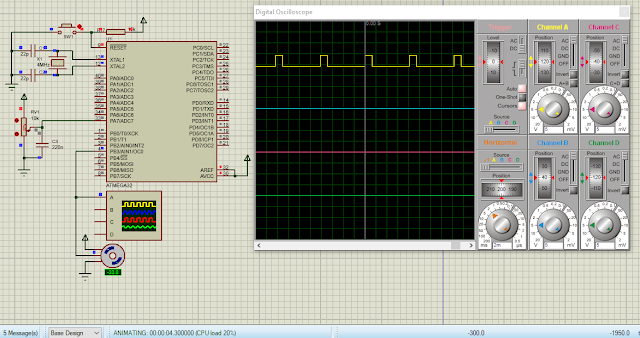

Controlling the position needs a specific timing. Conventionally, the signal timing frequency is 50 Hz. For more information about the servo motor timing, see this post.

Servo motors are available in many physical sizes and interfaces. Choosing a servo motor depends on the application. With Arduino, there are many libraries to interface with external hardware module, including the servo motor. The Servo.h is already available after the installing of Arduino IDE. Servo control pin can be any where within the digital I/O pin and it's selected by source code writing.

To use the servo library we must #include <Servo.h>. Additionally, we must create a servo object, for example,

Servo sg90;

Using a very simple servo motor like the SG90 requires a few methods.

- attach() - sg90.attach(pin) : where pin is any pin on the Arduino board in use.

- write() - sg90.write(angle): where angle is between 0 and 190 degree.

Other sophisticated servo motors have an angle reading line. But we don't need it here, as a simple example.

|

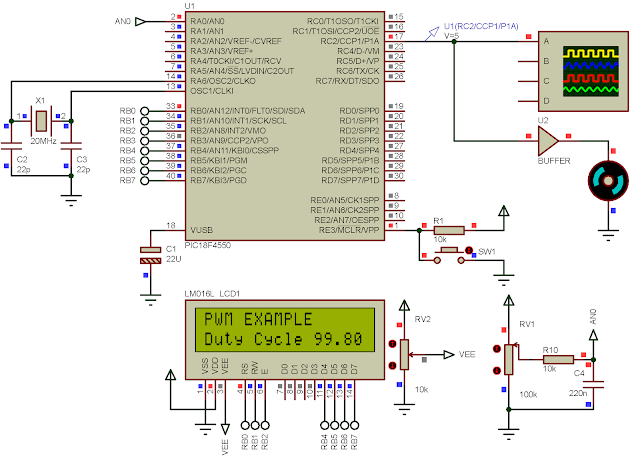

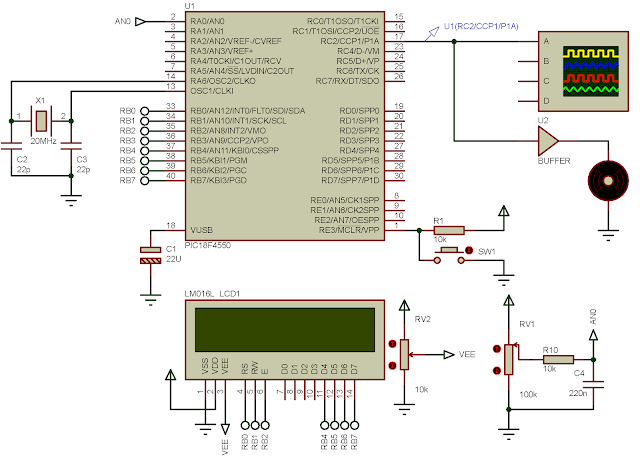

| SG90 servo from device's specification |

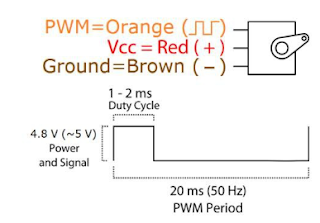

A typical servo SG90 has three lines - GND, VCC and Control. Control and VCC line requires a +5V pulse. Control line is the orange one's. It's no other than a PWM signal with low frequency.

|

| SG90 pin diagram and its timing from the device's specification |

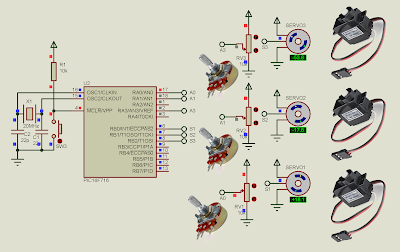

In this example post, I use three tactile switches to rotate a SG90 servo motor with three corresponding angles 0 , 90 and 180 degrees respectively. I use four pin A0, A1, A2 and A3.

|

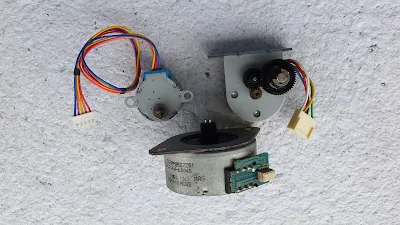

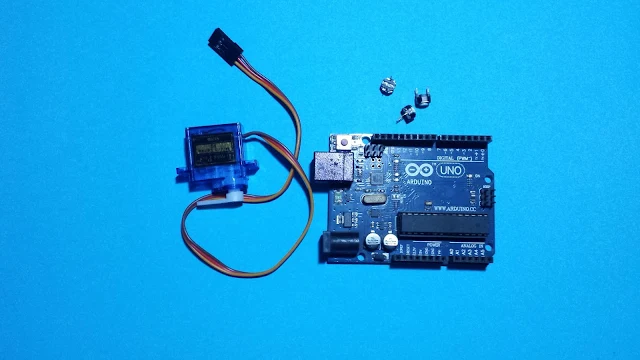

| Some required parts |

|

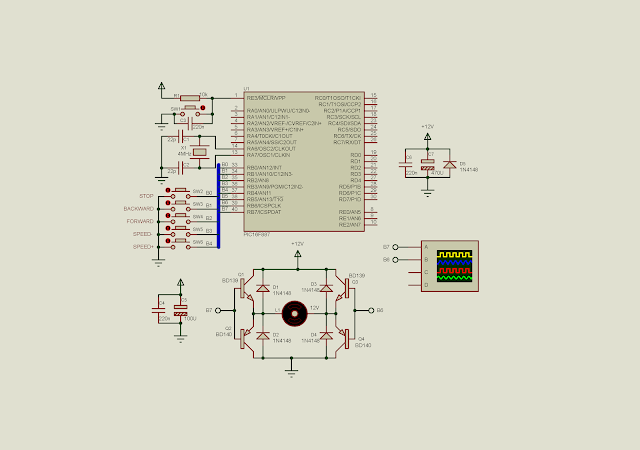

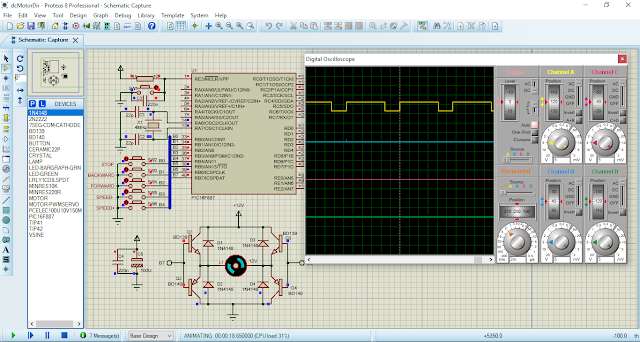

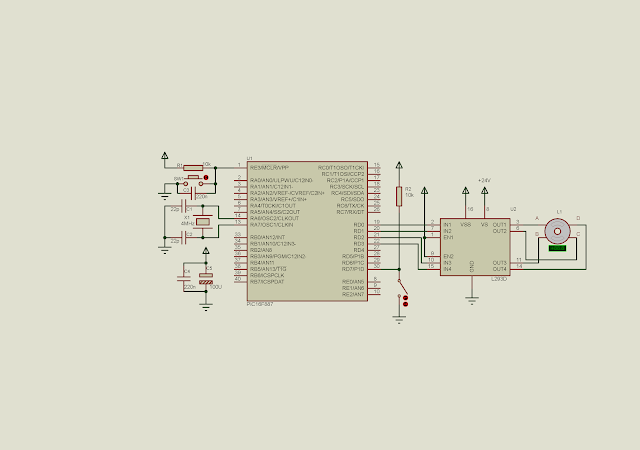

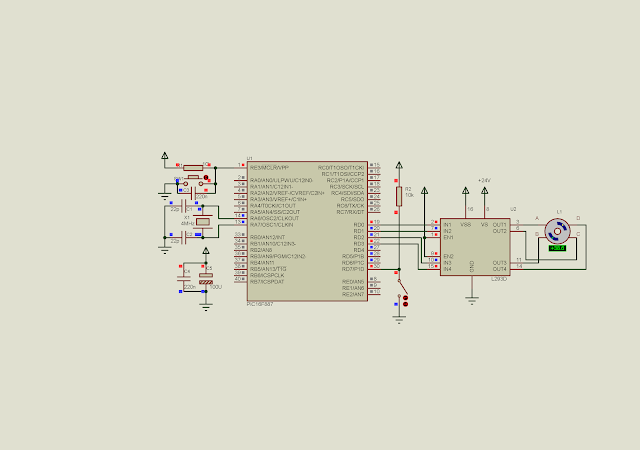

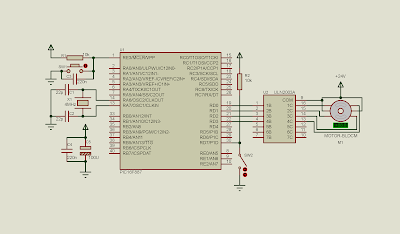

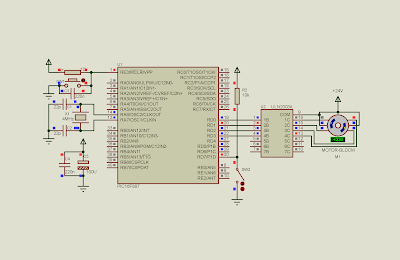

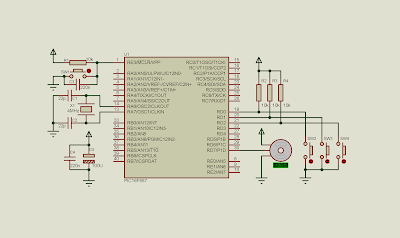

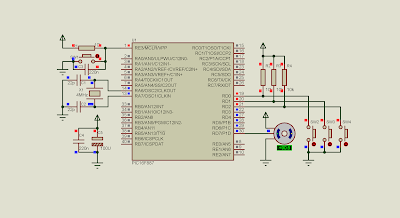

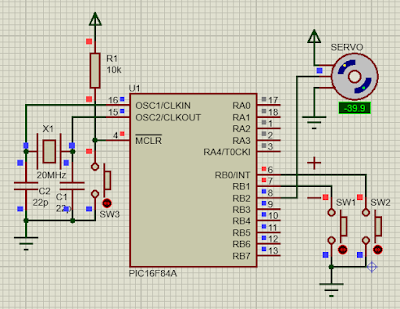

| Connections Diagram |

Arduino code from Github gist lists below.

Click here to download Arduino sketch.