/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* <h2><center>© Copyright (c) 2023 STMicroelectronics.

* All rights reserved.</center></h2>

*

* This software component is licensed by ST under BSD 3-Clause license,

* the "License"; You may not use this file except in compliance with the

* License. You may obtain a copy of the License at:

* opensource.org/licenses/BSD-3-Clause

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

void delay(uint16_t num){

for(uint16_t i=0;i<num;i++);

}

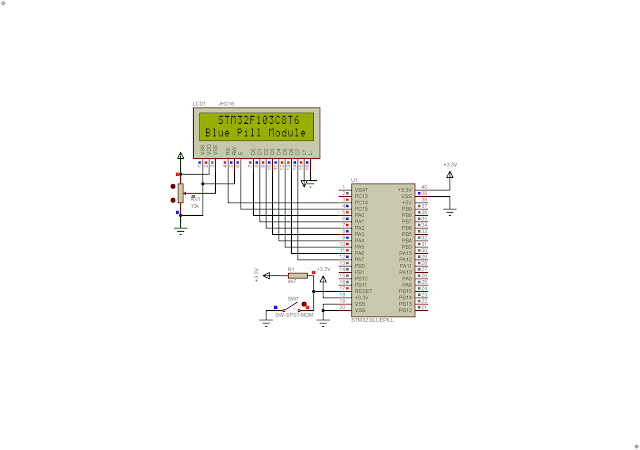

void lcdCommand(uint16_t cmd){

GPIOA->ODR=cmd;

//GPIOB->ODR&=~(1<<RS_Pin);

HAL_GPIO_WritePin(RS_GPIO_Port,RS_Pin,GPIO_PIN_RESET);

//GPIOB->ODR|=(1<<EN_Pin);

HAL_GPIO_WritePin(EN_GPIO_Port,EN_Pin,GPIO_PIN_SET);

//HAL_Delay(1);

delay(100);

//GPIOB->ODR&=~(1<<EN_Pin);

HAL_GPIO_WritePin(EN_GPIO_Port,EN_Pin,GPIO_PIN_RESET);

//HAL_Delay(10);

delay(10000);

}

void lcdData(uint8_t data){

GPIOA->ODR=data;

//GPIOB->ODR|=(1<<RS_Pin);

HAL_GPIO_WritePin(RS_GPIO_Port,RS_Pin,GPIO_PIN_SET);

//GPIOB->ODR|=(1<<EN_Pin);

HAL_GPIO_WritePin(EN_GPIO_Port,EN_Pin,GPIO_PIN_SET);

//HAL_Delay(1);

delay(10);

//GPIOB->ODR&=~(1<<EN_Pin);

HAL_GPIO_WritePin(EN_GPIO_Port,EN_Pin,GPIO_PIN_RESET);

//HAL_Delay(10);

delay(1000);

}

void lcdInit(void){

//GPIOB->ODR&=~(1<<RS_Pin);

HAL_GPIO_WritePin(EN_GPIO_Port,EN_Pin,GPIO_PIN_RESET);

//HAL_Delay(2);

delay(20000);

lcdCommand(0x38);

lcdCommand(0x0F);

lcdCommand(0x01);

//HAL_Delay(20);

delay(20000);

lcdCommand(0x06);

}

void lcdGotoXy(unsigned char x,unsigned char y){

unsigned char charAddr[]={0x80,0xC0,0x94,0xD4};

lcdCommand(charAddr[y-1]+x-1);

//HAL_Delay(1);

delay(1000);

}

void lcdPrint(char *str){

unsigned char i=0;

while(str[i]!=0){

lcdData(str[i]);

i++;

}

}

void lcdClear(void){

lcdCommand(0x01);

delay(100);

}

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

static void MX_GPIO_Init(void);

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* Configure the system clock */

SystemClock_Config();

/* Initialize all configured peripherals */

MX_GPIO_Init();

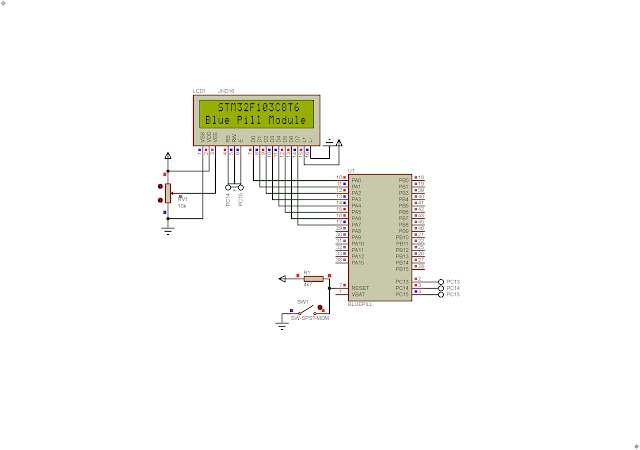

lcdInit();

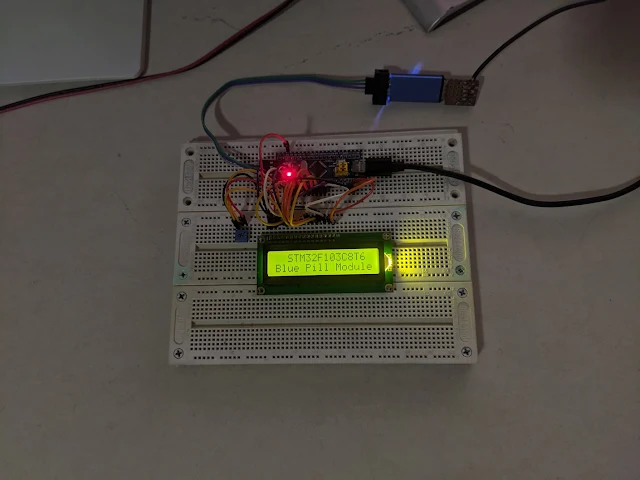

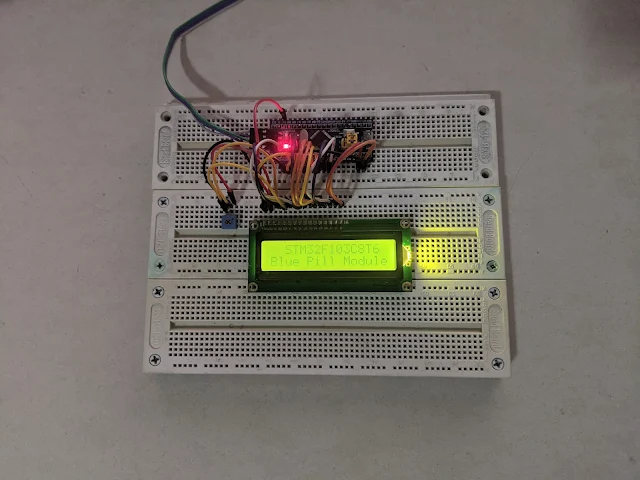

lcdGotoXy(3,1);

lcdPrint("STM32F103C8T6");

lcdGotoXy(1,2);

lcdPrint("Blue Pill Module");

for(uint8_t i=0;i<200;i++) delay(50000);

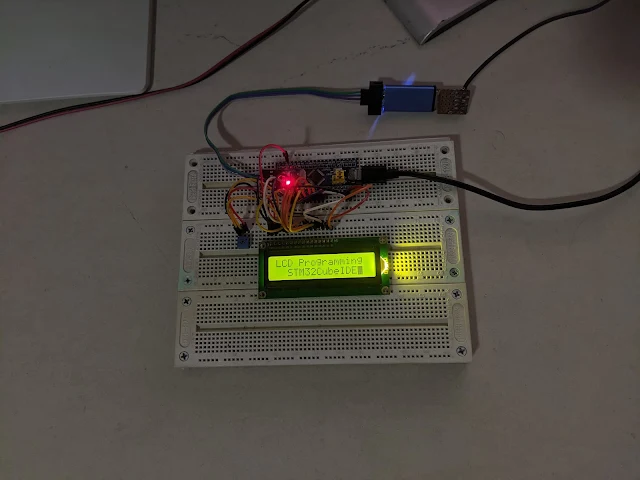

lcdClear();

lcdGotoXy(1,1);

lcdPrint("LCD Programming");

lcdGotoXy(3,2);

lcdPrint("STM32CubeIDE");

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

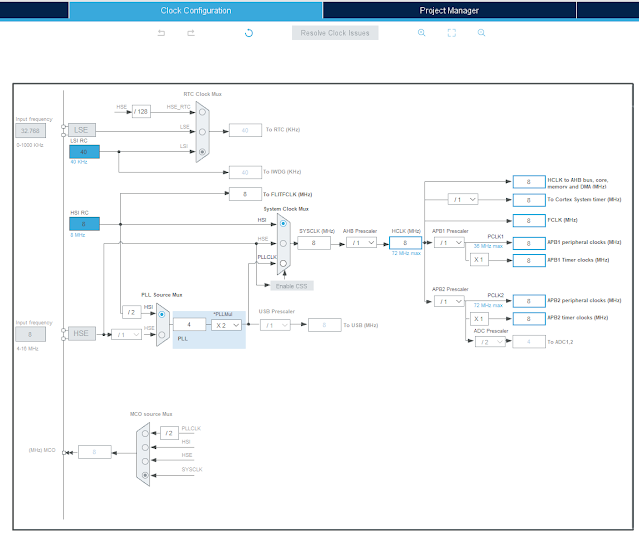

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSI;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.HSICalibrationValue = RCC_HSICALIBRATION_DEFAULT;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_NONE;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_HSI;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV1;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_0) != HAL_OK)

{

Error_Handler();

}

}

/**

* @brief GPIO Initialization Function

* @param None

* @retval None

*/

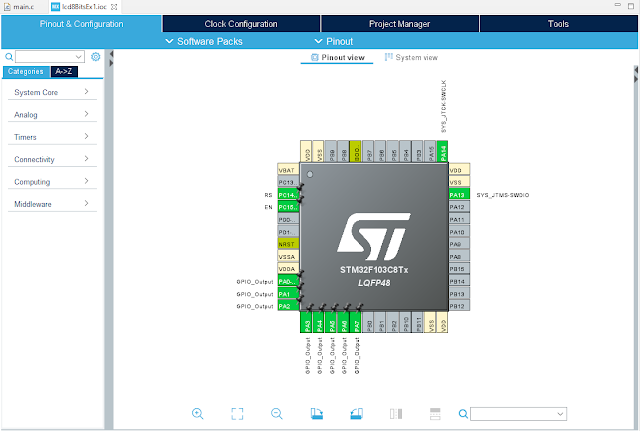

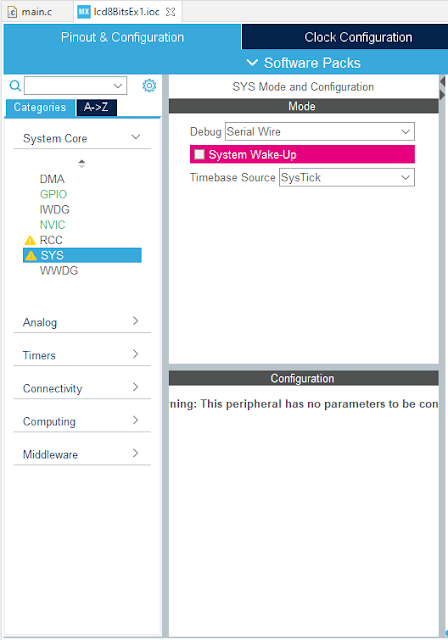

static void MX_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

/* GPIO Ports Clock Enable */

__HAL_RCC_GPIOC_CLK_ENABLE();

__HAL_RCC_GPIOA_CLK_ENABLE();

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(GPIOC, RS_Pin|EN_Pin, GPIO_PIN_RESET);

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(GPIOA, GPIO_PIN_0|GPIO_PIN_1|GPIO_PIN_2|GPIO_PIN_3

|GPIO_PIN_4|GPIO_PIN_5|GPIO_PIN_6|GPIO_PIN_7, GPIO_PIN_RESET);

/*Configure GPIO pins : RS_Pin EN_Pin */

GPIO_InitStruct.Pin = RS_Pin|EN_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

HAL_GPIO_Init(GPIOC, &GPIO_InitStruct);

/*Configure GPIO pins : PA0 PA1 PA2 PA3

PA4 PA5 PA6 PA7 */

GPIO_InitStruct.Pin = GPIO_PIN_0|GPIO_PIN_1|GPIO_PIN_2|GPIO_PIN_3

|GPIO_PIN_4|GPIO_PIN_5|GPIO_PIN_6|GPIO_PIN_7;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct);

}

/* USER CODE BEGIN 4 */

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

/************************ (C) COPYRIGHT STMicroelectronics *****END OF FILE****/

.jpg)